Products

What we produce?

We are always ready and eager to be a competent partner providing sophisticated interlinings solutions.

We have a vast product portfolio including a wide variety of bespoke products.

We employ a variety of post-processing methods such as garment wash, stone wash and garment dying.

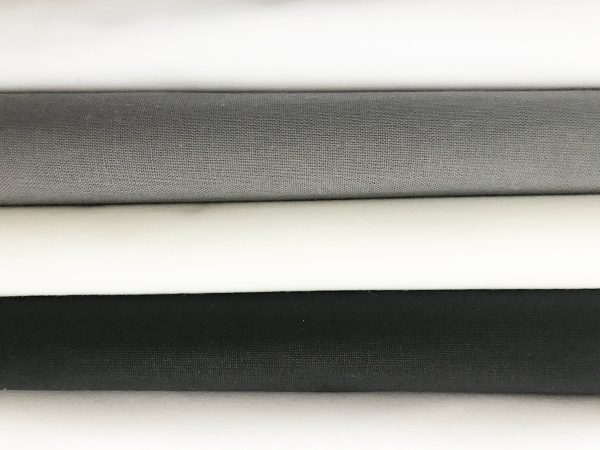

Woven Cotton

- High bonding strength

- Resilient and soft touch

- Good dimensional stability and bonding strength after washing

- Shows excellent shrinkage rate to ensure stable appearance

- Assures freedom from bubbling or delamination throughout the life of the garments

- Dry cleanable

- No yellowing

- Fusible Weight range: 60 – 220 gm/m2

- Non-Fusible Weight range: 40 – 175 gm/m2

- Collar, box plate, pocket flap

- Shoulder placket and cuff

- Pocket sta

Woven Polyester Cotton

- High bonding strength

- Resilient and soft touch

- Good dimensional stability and bonding strength after washing

- Shows excellent shrinkage rate to ensure stable appearance

- Good wash ability and resistance to care treatments

- Suitable for ‘wrinkle free’ garments

- Assures freedom from bubbling or delamination throughout the life of the garments

- Washable up to 90°c

- No yellowing

- Fusible Weight range: 70- 300 gm/m2

- Non-Fusible Weight range: 40 – 200 gm/m2

- Collar, box plate, pocket flap

- Shoulder placket and cuff

- Pocket sta

Knit Stretch Polyester

- High bonding strength

- Resilient and soft touch

- Good dimensional stability and bonding strength after washing

- Better elasticity in both (horizontal and vertical) direction

- Assures freedom from bubbling or delamination throughout the life of the garments

- Resistant to:

- Washing up to 90°

- Dry cleaning

- Enzyme washing

- Circular Knit: 20 – 100 gm/m2

- Warp knit (weft insert): 35 – 120 gm/m2

- Collar, lapel and front of blazer, suits & jackets, waist band

- Inner side of babies wear

- Back side shelter of embroidery

Non Woven

- Thermal bonded product with paste dot coating and double dot coating by PES and PA adhesive

- Chemical bonded product with paste dot coating and scatter dot coating by PES, PA and LDPE adhesive

- Shows low heat shrinkage rate and smooth touch

- Super soft and resilient to handle after fusing

- Shows good dot shape and retain its drapability after bonding with fabrics

- Resist ‘strike back’ due to fine dot pattern of the adhesive

- Shows excellent shrinkage rate to ensure stable appearance

- Resistant to:

- Washing up to 90°

- Dry cleaning

- Enzyme washing

- Fusible Weight range: 22- 90 gm/m2

- Non-Fusible Weight range: 16 – 80 gm/m2

- Collar, cuff & box plate of shirt & blouse

- Pocket flap & front

- Jackets and overcoats

- Pocket sta & waist band

Woven Stretch Polyester

- High bonding strength

- Soft touch

- Good dimensional stability & bonding strength after washing

- Better elasticity in horizontal direction

- Assures freedom from bubbling or delamination

- Resistant to:

- Washing up to 90°

- Dry cleaning

- Enzyme washing

- Circular Knit: 20 – 100 gm/m2

- Warp knit (weft insert): 20 – 200 gm/m2

- Collar, lapel and front of blazer, suits & jackets, waist band

- Inner side of babies wear

- Inner side of ladies wear

Thermoadhesive Tape

- Low heat shrinkage rate

- No strike back

- Easy for sewing

- Good shape recovery

- Good surface appearance and well bonding strength after fusing

- Plain

- Dot

- Web

- Weight range: 10 – 30 gm/m2

- Width range: <7mm

- Arm hole, sleeve seam of top

- Wrinkle free shirt

- Casual non iron shirt